Automation for High-Mix CNC Machining

Multiple AX Models for Your Production

Multiple AX Models for Your Production

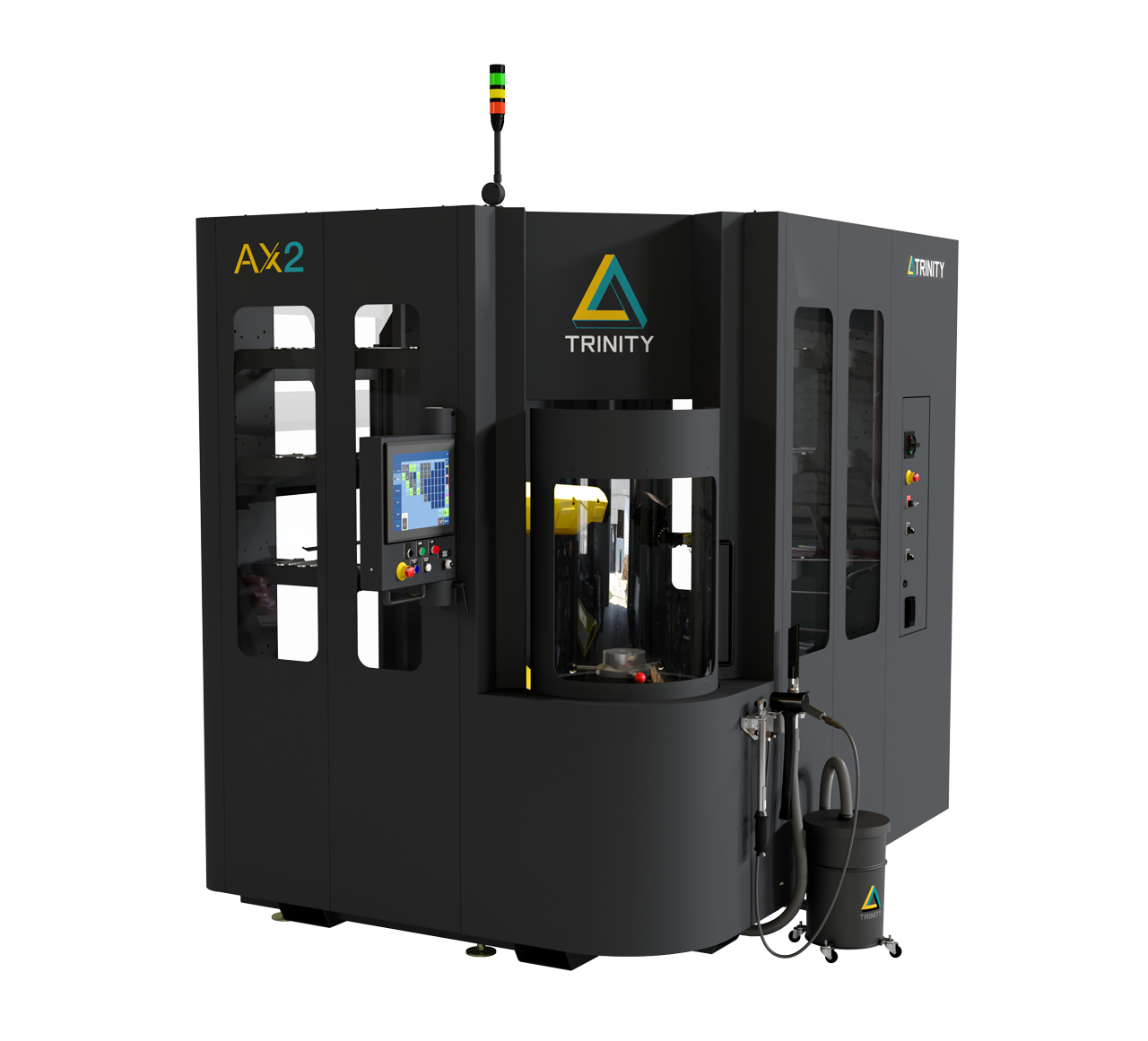

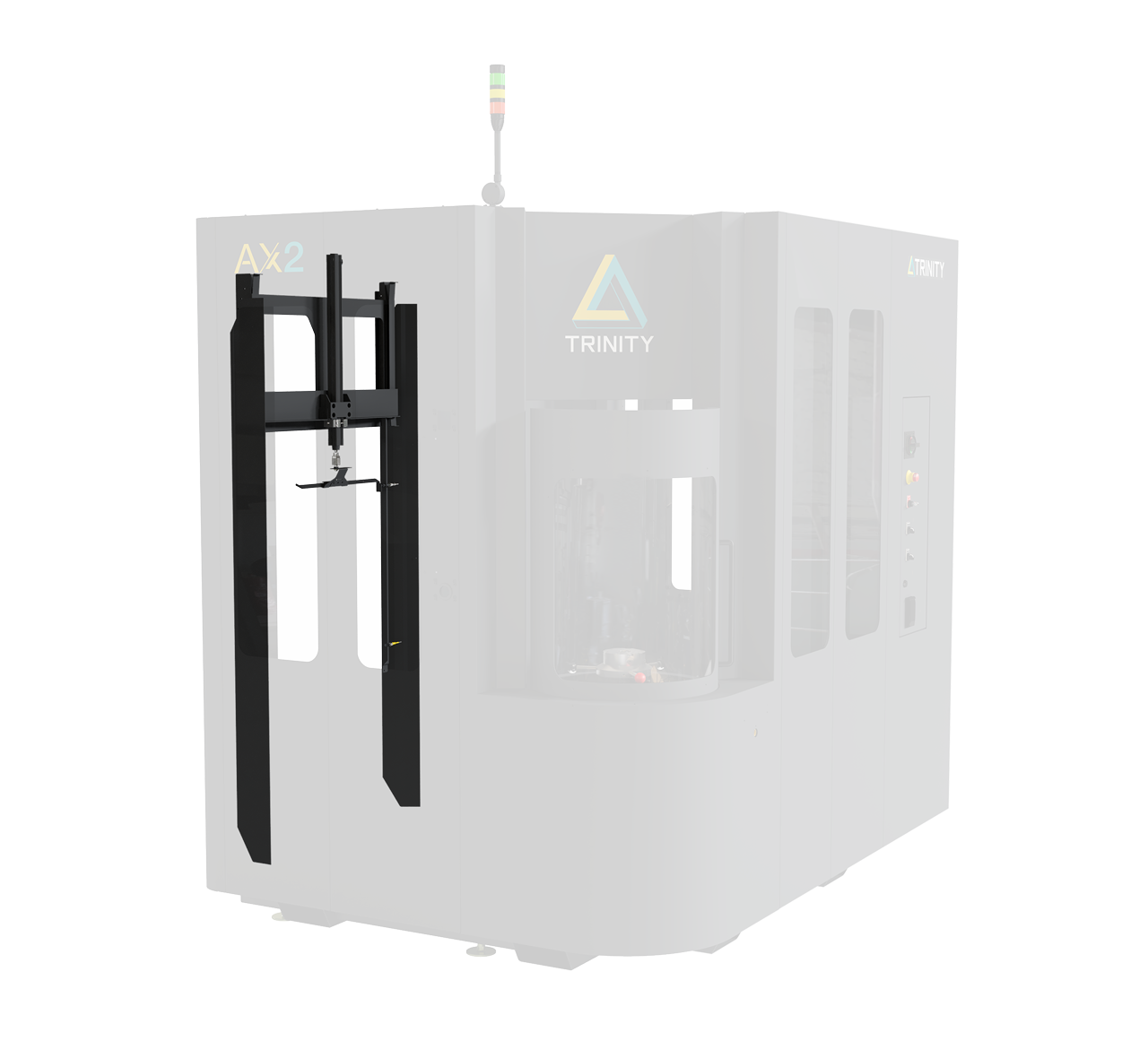

AX System

The Trinity AX system is designed to transform your CNC machine into a fully palletized automation system. The side load design is ideal for most machine shops, and its compact footprint requires minimal floor space. The integrated Trinity AX controller allows for simple-to-use controls. Whether you have a high mix / low volume or high mix / high volume demand the Trinity AX will improve your production throughput, freeing up your time for more critical tasks.

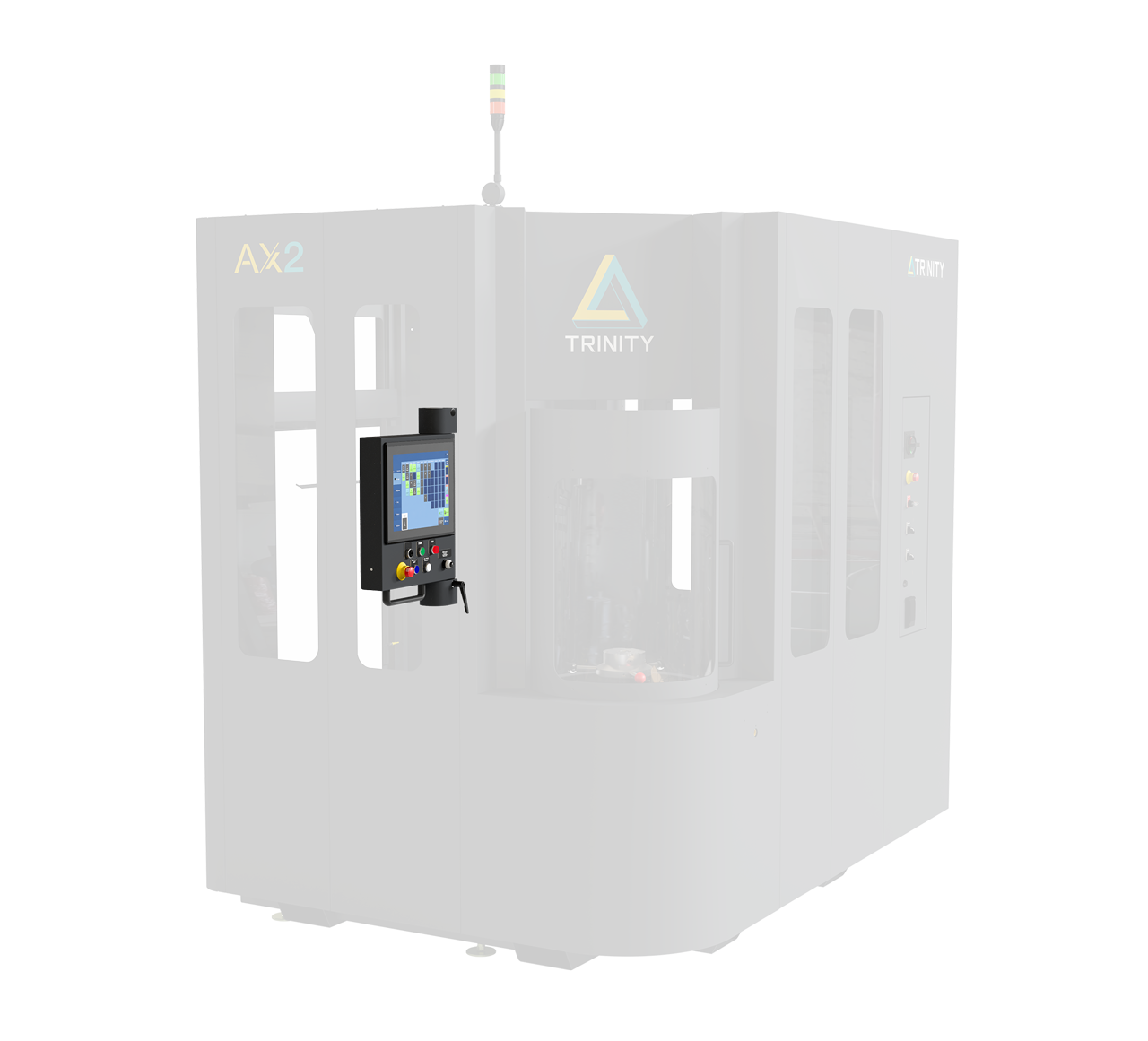

Trinity Cell Controller

- Simple, Easy to Use 15” Operator Touch Screen with IP67 screen rating

- Production is controlled in Auto by the HMI at the load station of the AX System

- Operators select programs from a drop-down menu on the AX Cell Controller

- Production monitoring screens give a quick visual representation of current production status

- Commonly used commands tied to quick access buttons for quicker loading/unloading

- Allows for activation / de-activation of any pallet location

- Provides real-time constantly updated cycle time analysis

- I/O and full access to the AX product health including robot data, system data, and production data

- AX series interface displays available programs on the integrated machining center

- CNC programs reside on the machining center

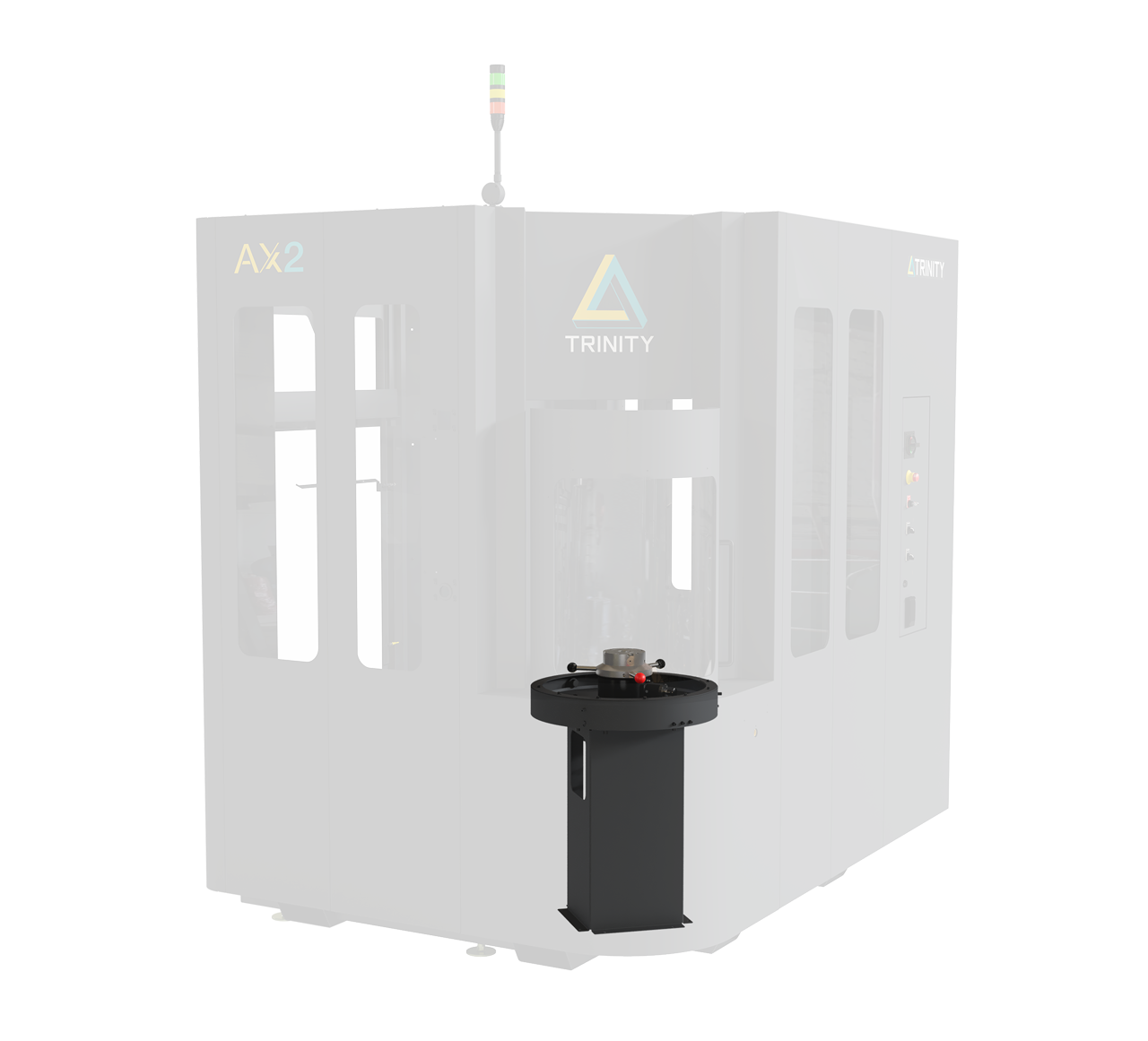

Operator Rotary Load/Unload Station

- Access to all sides of work holding and workpiece

- Large thrust bearing for heavy-duty stable rotation

- Stainless steel components

- Spring plunger to indicate four distinct defined positions (90 degrees apart)

- Heavy-duty overall construction

- Integrated SCHUNK Vero-S receiver

- Large handles for easy rotation by operators

- Integrated proximity sensor for zero position for guaranteed picking by robot

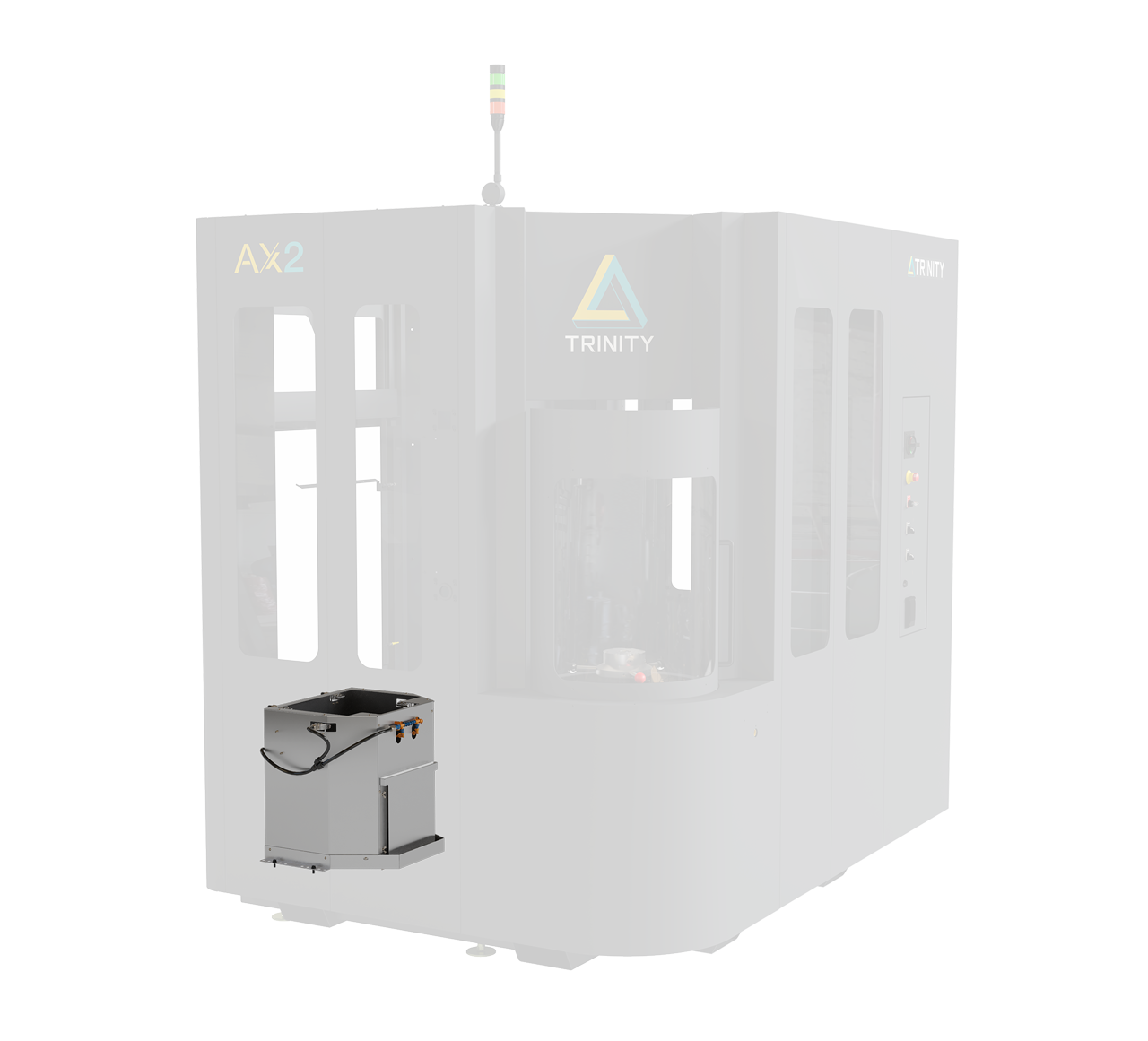

Integrated Part/Pallet Dryer

- Stainless steel sheet metal construction with integrated air-knife blow off

- Integrated into the AX system for workpiece, work holding, and pallet cleaning

- Ensures clean, dry parts return to the pallet storage locations

- Integrated lower tray captures any residual chips and coolant

- Reduces debris in system & on shop floor

- Eliminates blow off at the load station by operators

- Reduces overall production noise and chips

- Easily accessible debris removal tray allows for cleaning from outside the cell

Autodoor - On-site Machine Retrofit

- Modifications can be made to existing customer machines to be performed at customer facility

- Work holding pneumatic retrofit of to enable pallet receiver to be placed in existing machine

- On-site auto-door retrofit (including hardware and labor to retrofit existing machine)

- On-site rotary union integration (if required)

- On-site controls interface to link AX system with existing customer machine

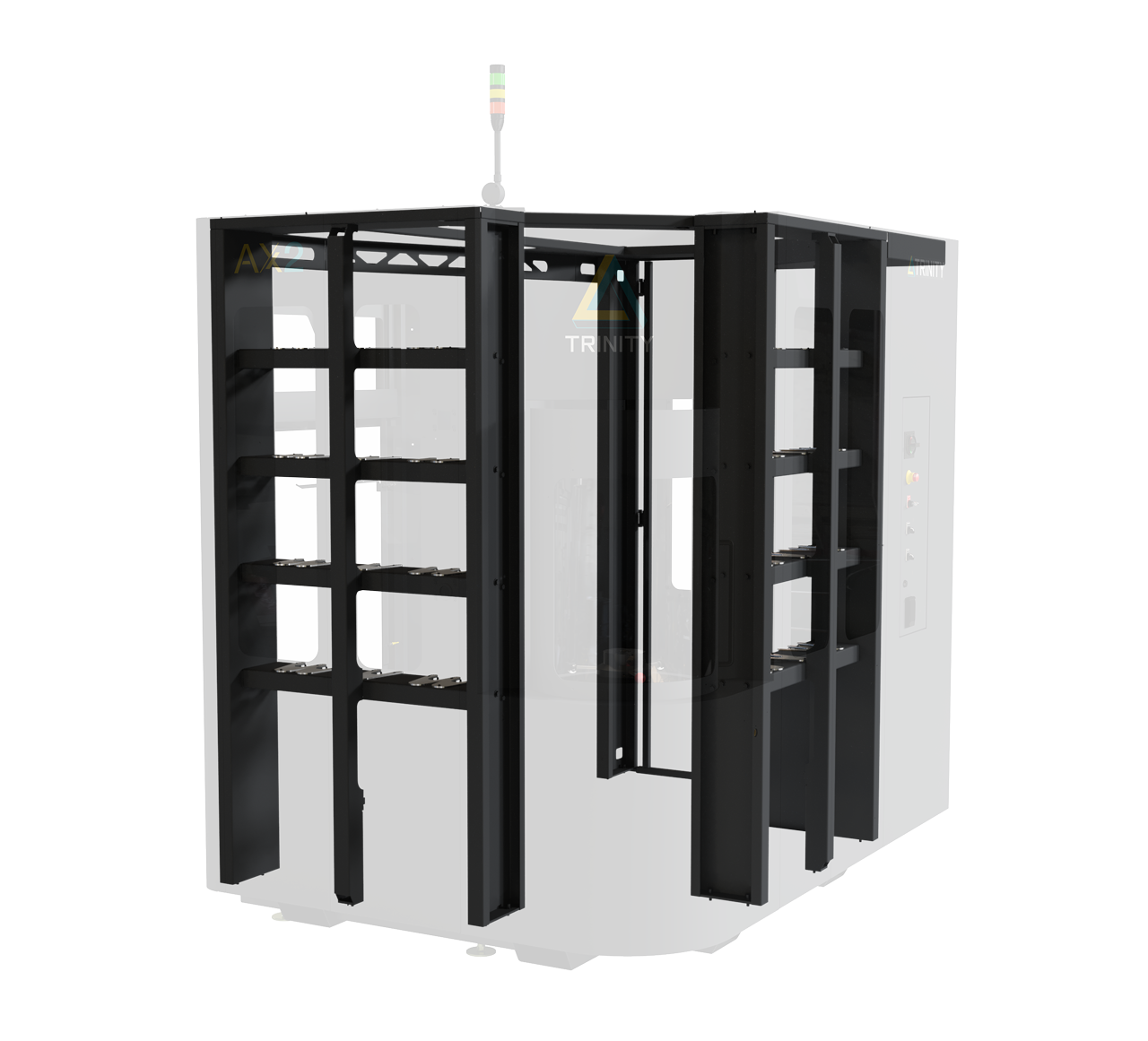

Pallet Location Shelves

- Reinforced Pallet Location Trays to reduce wear & tear on system/pallets

- Standardized system frames make for easy repair & assembly

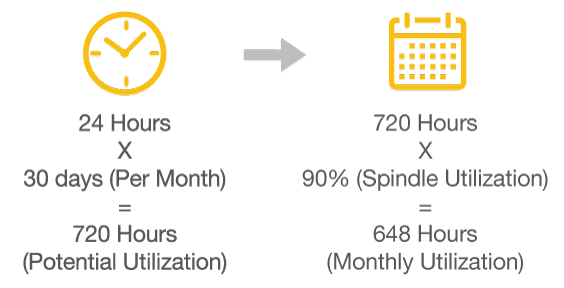

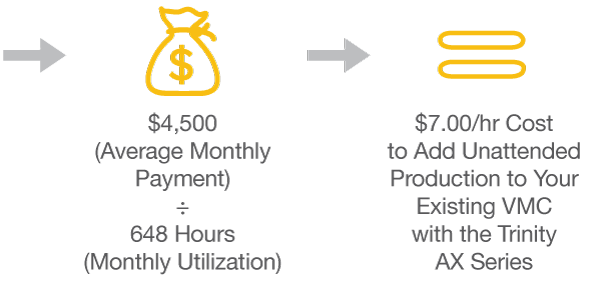

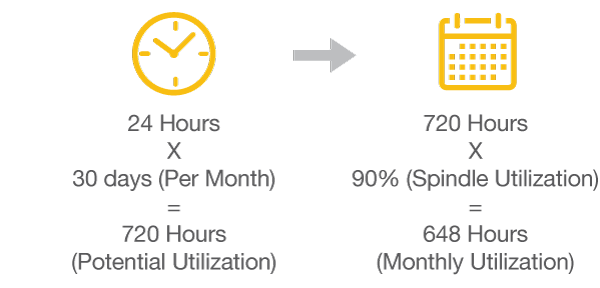

Lights Out Production for less than $10/hr

What does it cost to Automate a CNC with a Trinity AX?

Turn Your 5-Axis CNC Into An Automated Production System

From our Tech Center in Silicon Valley to Customer Shop Floors, see the Trinity AX in action.

https://6186738.fs1.hubspotusercontent-na1.net/hubfs/6186738/Video-BG/Trinity%20WESTEC%20Edit%20ver1.2-web.mp4

Unlock the potential of your CNC